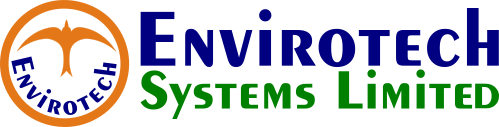

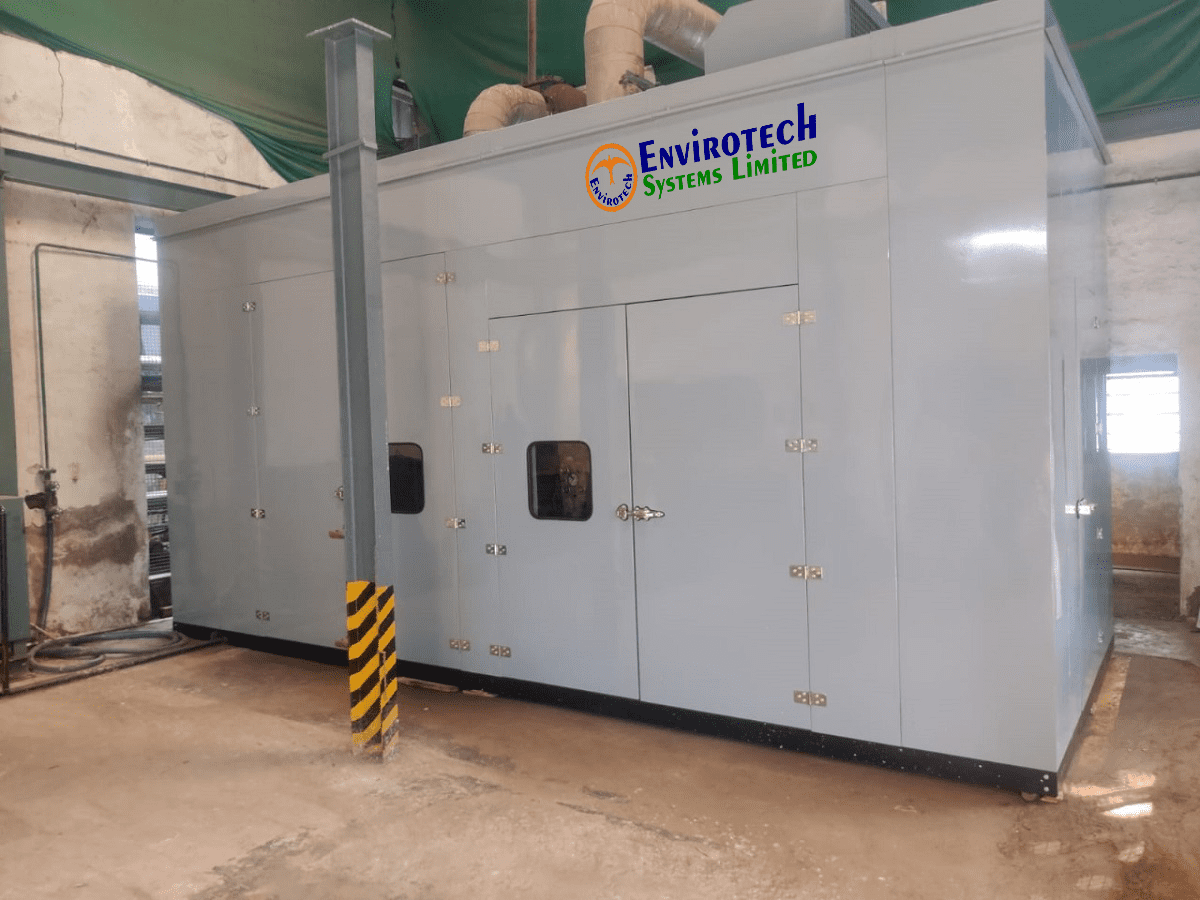

We manufacture Acoustic Enclosure For DG Set in various sizes, models, and designs keeping in mind the requirement of the client. We provide noise absorption technology in the diesel generating sets which highly reduces noise emission. It is vital that noise is managed by the machine supplier and employer, rather than relying on the user to wear ear plugs, ear defenders, or similar PPE because damage to hearing is typically cumulative, and till the damage is done the person isn’t aware of the damage at the time of exposure.

Acoustic Enclosure help in reducing noise by providing an enclosed environment for noisy machines with proper air ventilation. Sound waves which are above 85 decibels are dangerous for an individual living near highways and sideways and can lead to headaches, irritation, increased allergy symptoms, sleep deprivation, and other health problems. Acoustic enclosures get rid of offensive noise by dampening or reducing it.

Features Of Acoustic Enclosure For Diesel Generator sets

- Noise reductions according to CPCB Norms /as per ISO 14001 requirements for industrial applications.

- Controlled environment for temperature, humidity, cleanliness, and vibration isolation.

- Hinge-type doors of the required size, doors are fitted with a Gasket to block noise leakage from the gap.

- Spring-loaded lock, openable from both sides.

- Rainwater protection hood to corner for fresh air inlet acoustic louvers.

- Electrical wiring, switchboard & light to maintain 300 LUX inside the enclosure.

- All Hardware was Zinc passivated to avoid rusting & door hinges are SS.

- Provided cutouts in the acoustic panel for pipe/cable entry or any other requirement.

- Two coats of primer & automotive paint in the desired shade.

- Acoustically treated louvers on the roof of the Acoustic Enclosure for air inlet & exhaust.